The particle size distribution (PSD) of a milk powder determinates its appearance, the reconstitution properties, the surface reactivity, and the flow characteristics. The measurement of these parameters by means of well-defined test methods is important because they intrinsically affect the powder behaviour. In spite of the raw milk standardization, the carefully defined technological parameters and the rigorous quality assurance procedures adopted in the production plants, some unacceptable variations may remain between different batches of milk powder (Nielsen et al.

Milk powder manufacturers use worldwide many resources to ensure products with good sensory quality and longer shelf life. The variability of the milk powders properties comes from the raw material, the different drying methods and the numerous chemical reactions that could happen during storage because of the temperature, relative humidity and time. The basic quality indicators of milk powders are both their chemical composition and their physical properties (particle size, density, flowability, solubility, water activity, etc.). Moreover, milk powders are frequently used for convenience in transportation, handling, processing, and product formulations but they are highly susceptible to various changes such as moisture uptake, softening, browning, compaction, collapse or caking (Al Mahdi et al. spray drying and roller drying), in order to prevent the growth of microorganisms and inhibit enzymatic reactions. Milk is an extremely perishable product and yet it could be preserved for later consumption by removing water by means of drying methods (i.e. In conclusion a detailed knowledge of functional properties of milk powders may allow the dairy to tailor the products to the user and help the food processor to perform a targeted choice according to the intended use.

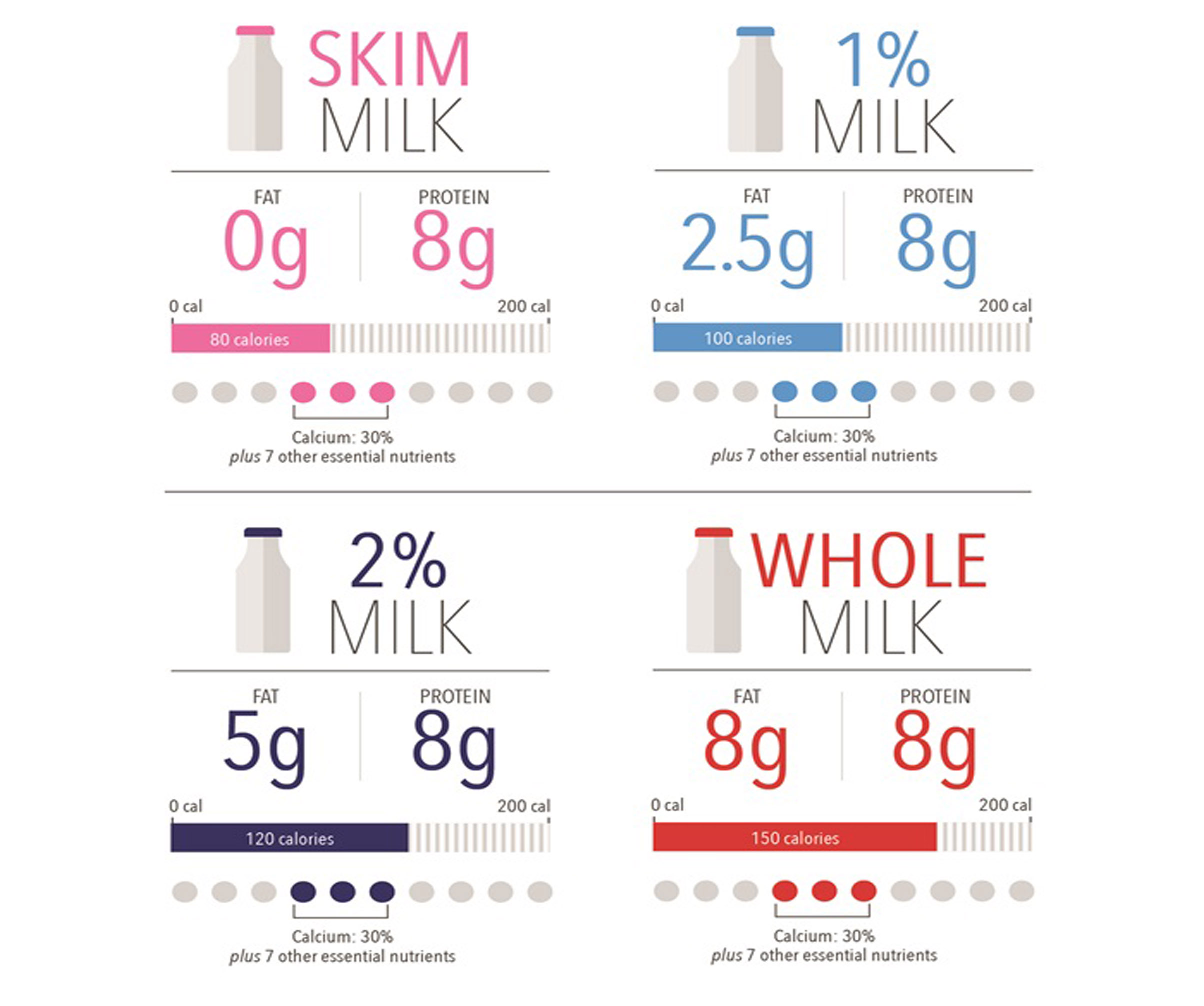

Colour analysis underlined the relevant contribution of fat content and particle size, resulted in higher lightness ( L*) for skim milk powder than whole milk powder, which, on the other hand, showed higher yellowness ( b*) and lower greenness (− a*). The insolubility index of the spray-dried skim and whole milk powders, measured as weight of the sediment (from 0.5 to 34.8 mg), allowed a good discrimination of the samples. Flowability, measured by Hausner ratio and Carr’s index indicators, ranged from passable to poor when evaluated according to pharmaceutical criteria. The loose density of skim milk powders was significantly higher than whole milk powders (541.36 vs 449.75 kg/m 3). For all the samples the size distribution was quite narrow, with a span value less than 2. Particle sizes of the spray-dried skim milk powders, measured as volume and surface mean diameter were significantly lower than that of the whole milk powders, while the roller dried sample showed the largest particle size. In general, except for the values of water activity, the physical properties of skim and whole milk powders are very different. These physical properties are crucial both for the management of milk powder during the final steps of the drying process, and for their use as food ingredients. The lack of updated knowledge about the physical properties of milk powders aimed us to evaluate selected physical properties (water activity, particle size, density, flowability, solubility and colour) of eleven skim and whole milk powders produced in Europe.

0 kommentar(er)

0 kommentar(er)