All transactions are done in other sections directly influence the stock.Ĥ.

Manufacturing production software serial#

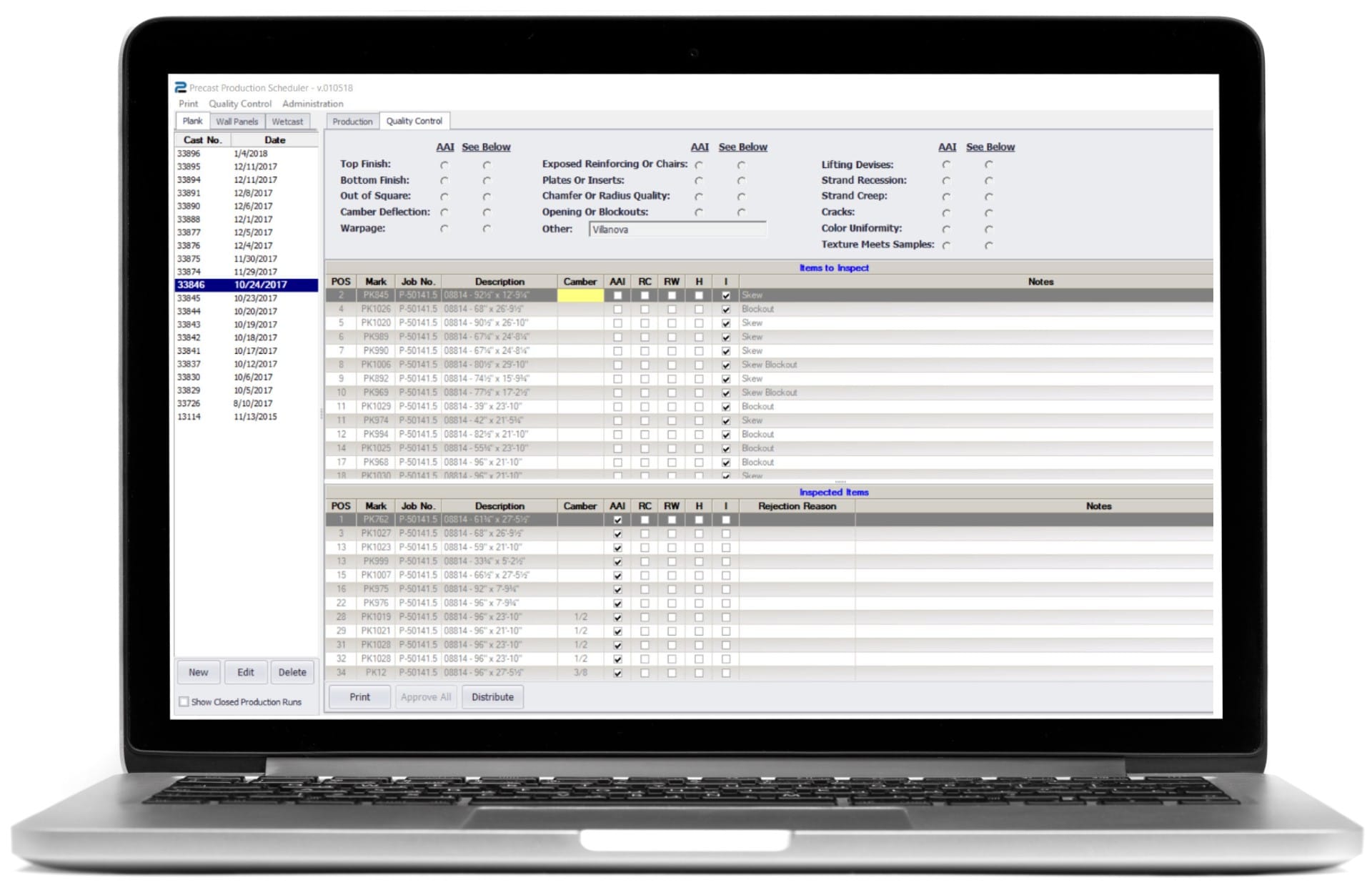

Then there’s Stock, for inventory control, stock movements, shipments, tracking of stock lots and serial numbers, and much more. There’s Production planning, where you can schedule operations and materials, see the visual production calendar and Gantt charts and use dynamic drag-and-drop rescheduling.ģ. The CRM section is for managing the sales side, where an order is tracked from quotation through invoicing and delivery.Ģ.

Manufacturing production software software#

MRPeasy manufacturing/production software has four core sections:ġ. In turn, the increased efficiency translates into greater profitability and growth of your company. Importantly, MRPeasy saves time on gathering information and planning, helps to provide accurate estimates of profitability and lead times and lowers inventory levels while preventing stock-outs. It combines the core processes sales, materials planning, production scheduling, shop floor reporting, inventory management, and procurement into one easy-to-use system. ERP solutions from QAD not only help manufacturers effectively adapt to change and disruptors, but also leverage them as a competitive advantage.MRPeasy manufacturing production software video transcript: MRPeasy is a Cloud-Based Manufacturing (MRP) Software for Small Manufacturers (10-200 employees) QAD enterprise planning software allows manufacturing businesses to rapidly and strategically respond to both internal and external business changes with seamless efficiency.

That means building in real-time reporting and visibility into business operations, the market, and your customers so you can make informed decisions. QAD delivers solutions to help manufacturers be intelligent, agile and innovative in an evolving business environment. QAD manufacturing ERP systems empower businesses to embrace change, keep pace with advanced technologies and get ahead of competitors. For that reason, manufacturers must stay in a position to proactively prepare rather than react to changes and disruptions. Business environments are constantly changing, and the practices and strategies relied on yesterday may not work tomorrow. These models can provide ERP users flexibility migrate between delivery models, or integrate benefits not available in existing implementations. “Hybrid ERP” deployment may offer a combination of on-premise and cloud-based hosting and deployment services for a manufacturing company.A cloud-based ERP system can provide manufacturers with a comprehensive yet flexible system with continual support, updates, training, and flexible customization from an ERP provider.

This includes the cost and risk associated with managing hardware and system infrastructure for manufacturers. An on-premise ERP system offers control, support and ownership of the system once implemented.There are many different types of ERP systems and deployment options available today that range greatly depending on the size, function, and needs of a manufacturing organization. The best manufacturing ERP solutions support Adaptive Manufacturing Enterprises with the ability to adapt to change and disruption enabling a competitive advantage. In general, a manufacturing ERP system streamlines operations and provides support that helps manufacturers grow the business and increase revenue while improving quality. Gaining the ability to adapt when faced with changes or disruption in the business environment.Centralizing operational and financial information for enhanced visibility and communication.Capturing real-time reporting for your operations that you can quickly access.Eliminating the need for multiple systems that don’t communicate with one another.Unifying departments and comparing metrics across the business.Mitigating risk and increasing confidence around compliance.Improving supply chain, warehouse, transportation, and inventory management.Optimizing manufacturing operations for enhanced productivity.Minimizing redundancy and automating processes to increase efficiency.

The most notable benefits of ERP for manufacturing companies include: There are many valuable operational and financial benefits to having a modern, integrated manufacturing ERP system, both at the micro and macro levels. Benefits of ERP for Manufacturing Companies

0 kommentar(er)

0 kommentar(er)